Kinematic Analysis

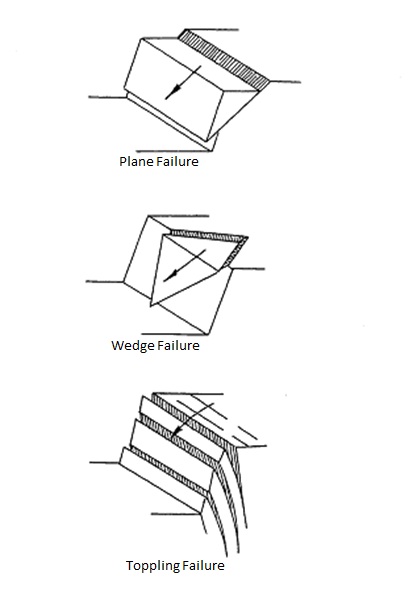

Kinematic analysis is a method used to analyze the potential for the

various modes of rock slope failures (plane, wedge, toppling failures),

that occur due to the presence of unfavorably oriented discontinuities

(Figure 1). Discontinuities are geologic breaks such as joints, faults,

bedding planes, foliation, and shear zones that can potentially serve as

failure planes. Kinematic analysis is based on Markland’s test which is

described in Hoek and Bray (1981). According to the Markland’s test, a

plane failure is likely to occur when a discontinuity dips in the same

direction (within 200) as the slope face, at an angle gentler

than the slope angle but greater than the friction angle along the

failure plane (Hoek and Bray, 1981) (Figure 1). A wedge failure may

occur when the line of intersection of two discontinuities, forming the

wedge-shaped block, plunges in the same direction as the slope face and

the plunge angle is less than the slope angle but greater than the

friction angle along the planes of failure (Hoek and Bray, 1981) (Figure

1). A toppling failure may result when a steeply dipping discontinuity

is parallel to the slope face (within 300) and dips into it

(Hoek and Bray, 1981). According to Goodman (1989), a toppling failure

involves inter-layer slip movement. The requirement for the occurrence

of a toppling failure according to Goodman (1989) is “If layers have an

angle of friction Φj, slip will occur only if the direction of the

applied compression makes an angle greater than the friction angle with

the normal to the layers. Thus, a pre-condition for interlayer slip is

that the normals be inclined less steeply than a line inclined Φj above

the plane of the slope. If the dip of the layers is σ, then toppling

failure with a slope inclined α degrees with the horizontal can occur if

(90 - σ) + Φj < α”.

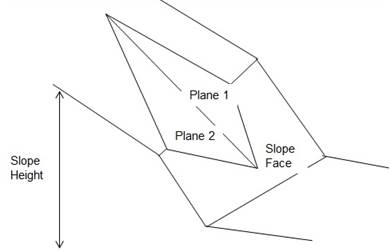

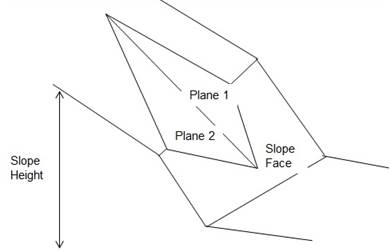

Figure 1: Slope failures associated with unfavorable orientation of

discontinuities (modified after Hoek and Bray, 1981).

Stereonets are used for graphical kinematic analysis. Stereonets are

circular graphs used for plotting planes based on their orientations in

terms of dip direction (direction of inclination of a plane) and dip

(inclination of a plane from the horizontal). Orientations of

discontinuities can be represented on a stereonet in the form of great

circles, poles or dip vectors. Clusters of poles of discontinuity

orientations on stereonets are identified by visual investigation or

using density contours on stereonets (Hoek and Bray, 1981). Single

representative orientation values for each cluster set is then assigned.

These single representative orientation values, can be the highest

density orientation value within a cluster set, or the mean dip

direction/dip of a pole cluster as calculated using equations in

Borradaille (2003).

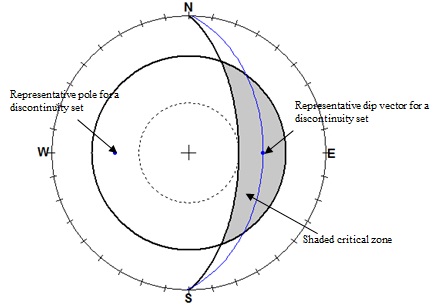

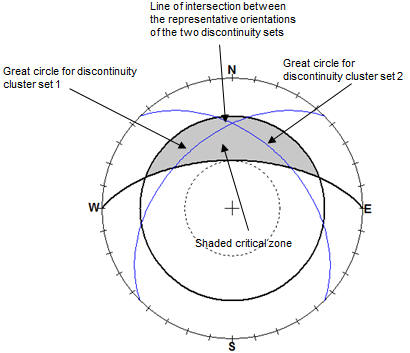

Great circles for representative orientation values along with great

circle for slope face and the friction circle are plotted on the same

stereonet to evaluate the potential for discontinuity-orientation

dependent failures (Figures 2,3,4) (Hoek and Bray, 1981). This

stereonet-based analysis is qualitative in nature and requires the

presence of tight data clusters for which a reasonably representative

orientation value can be assigned. The chosen representative value may

or may not be a good representation for a cluster set depending on the

tightness of data within a cluster. Tight circular data is more uniform

and has less variation making representative values more meaningful than

for cases where data shows a wide scatter. Fisher’s K value is used to

describe the tightness of a scatter (Fisher, 1953). It is calculated as

follows:

K = M – 1/M-|rn|, where M is no. of data within a cluster, and |rn| is the magnitude of resultant vector for the cluster set (Fisher, 1953).

High K values indicate tightly clustered data, i.e. well-developed

cluster set. If the cluster set is tight, the representative values are

more reliable and so is the stereonet-based kinematic analysis. However,

there are cases when a tight circular clustering of discontinuity

orientations does not exist. A different quantitative approach that does

not require tightly clustered discontinuity sets can be performed by

DipAnalyst 2.0. DipAnalyst 2.0

can also be used for the stereonet-based method.

Figure 2: Stereographic plot showing requirements for a plane failure

(Hoek and Bray, 1981, Watts 2003). If the dip vector (middle point of

the great circle) of the great circle representing a discontinuity set

falls within the shaded area (area where the friction angle is higher

than slope angle), the potential for a plane failure exists (figure

created using RockPack).

Figure 3: Stereographic plot showing requirements for a wedge failure

(Hoek and Bray, 1981, Watts 2003). If the intersection of two great

circles representing discontinuities falls within the shaded area (area

where the friction angle is higher than slope angle), the potential for

a wedge failure exists (figure created using RockPack software).

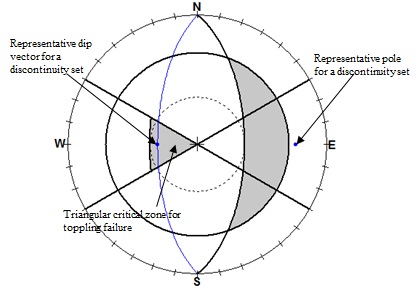

Figure 4: Stereographic plot showing requirements for a toppling failure

(Goodman, 1989, Watts 2003). The potential for a toppling failure exists

if dip vector (middle point of the great circle) falls in the triangular

shaded zone (figure created using RockPack software).

Factor of Safety Calculations

Limit equilibrium analysis is used to calculate the factor of safety

(F.S.) of a slope against failure if the kinematic analysis indicates

the potential for failure. Factor of safety is the ratio of the

resisting forces (shear strength) that tend to oppose the slope movement

to the driving forces (shear stress) that tend to cause the movement

along a plane of discontinuity. The equation for F.S. is:

F.S. = (c +

s

tan

f)/t

(13)

Where: F.S. = factor of safety

c = cohesion

f

= angle of internal friction

s

= normal stress on slip surface

t

= shear stress

According to the limit equilibrium approach, a factor of safety value

equal to 1 represents limiting condition. A value greater than 1

represents a stable slope, and a value less than 1 indicates an unstable

slope. The desired value of factor of safety depends upon the importance

of the slope and the consequences of failure. For heavily travelled

roads, slopes are usually designed to have a factor of safety equal to

or greater than 1.3 under saturated conditions, maximum loads, and worst

expected geological conditions (Canadian Geotechnical Society, 1992;

Wyllie and Mah, 2004). The equations derived for both plane and wedge

failure, consider weight of the sliding block, cohesion along plane of

discontinuity, effect of water present along planes of discontinuity and

tension applied from a rock bolt. Although the equations for factor of

safety calculations of plane and wedge failures are based on Equation

(13), they vary due to differences in the shape of the sliding block for

the case of plane vs. wedge failures. The methods for calculating the

factor of safety for plane and wedge failures with corresponding

equations to determine the resisting and driving forces, including the

effect of water pressure along discontinuities and application of a rock

bolt are given in Hoek and Bray (1981) and Wyllie and Mah (2004).

To calculate factor of safety for plane failure, DipAnalyst 2.0,

requires slope height, slope angle, discontinuity plane inclination,

position and depth of tension crack, and ground water conditions along

the discontinuity plane/tension crack (Figure 5).

For wedge failure,

DipAnalyst 2.0

follows the “short solution” put forward by Hoek and Bray (1981). The

solution requires slope height, slope angle, orientation of the two

intersecting planes (Figure 6). The “short solution” does not consider

the effect of a rock bolt, and the presence of a tension crack.

Figure 6: Components of wedge failure analysis.

REFERENCES

BORRADAILE, G., 2003,

Statistics of Earth Science Data:

Springer, New York, 351p.

CANADIAN GEOTECHNICAL SOCIETY, 1992, Canadian

Foundation Engineering Manual, BiTech Publishers Ltd.,

FISHER, R.,A., 1953,

Dispersion on a sphere:

Proceedings of the Royal society of London, A217, pp.295-305.

GOODMAN, R. E., 1989,

Introduction to Rock Mechanics:

John Wiley & Sons, New York, NY 562 p.

HOEK, E. and BRAY, J. W., 1981,

Rock Slope Engineering: The

Institute of Mining and Metallurgy, London, England, 358 p.